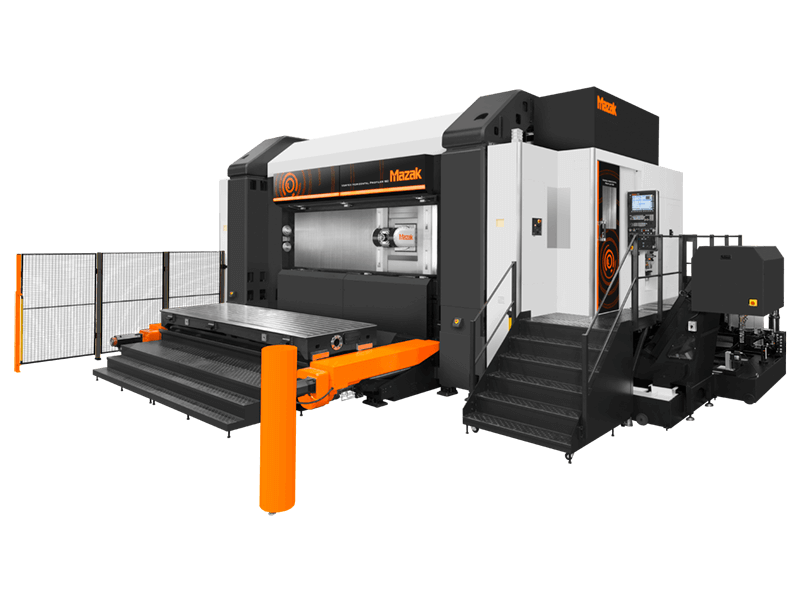

Mazak Machining Center for Large Workpiece Machining

The Vortex Horizontal Profiler 160 XP is a high-performance Mazak machining center built for precision and efficiency in large workpiece machining. Its rigid construction and thermally stable design maintain accuracy during long cutting cycles. The large 4000 mm × 1600 mm table supports oversized components with ease. In addition, X, Y, and Z-axis travels of 4200 mm, 1500 mm, and 550 mm provide the reach and stability required for demanding aerospace and heavy equipment applications.

Automated 5-Axis Machining for Complex Geometries

This Mazak machining center also delivers automated 5-axis machining for complex geometries in a single setup. The A-axis offers ±110 degrees of motion, while the C-axis provides full 360-degree rotation. These capabilities enable accurate multi-surface machining and reduce the need for multiple fixturing steps. As a result, the system shortens setup times, increases flexibility, and maintains consistent accuracy across large and intricate components.

MAZATROL SmoothAi Control for Advanced Performance

The Vortex Horizontal Profiler 160 XP features MAZATROL SmoothAi, which introduces intelligent programming, AI-driven diagnostics, and digital twin functionality. This advanced control improves cycle times, enhances material removal rates, and supports superior surface finishes. When paired with its large workpiece machining capacity and automated 5-axis machining, the system becomes a strong choice for aerospace machining applications that require both precision and reliability.