About AW Miller

Manufacturing engineers need reliable systems that deliver consistent performance across every stage of production. AW Miller Technical Sales provides CNC machining and industrial 3D printing solutions designed to strengthen operational efficiency. Machine Shops operating under demanding production schedules need solutions that streamline workflows and minimize downtime. Our technologies, supported by comprehensive service and application expertise, help engineers sustain performance and strengthen process control. This partnership-focused approach keeps operations running smoothly and empowers manufacturers to achieve long-term success..

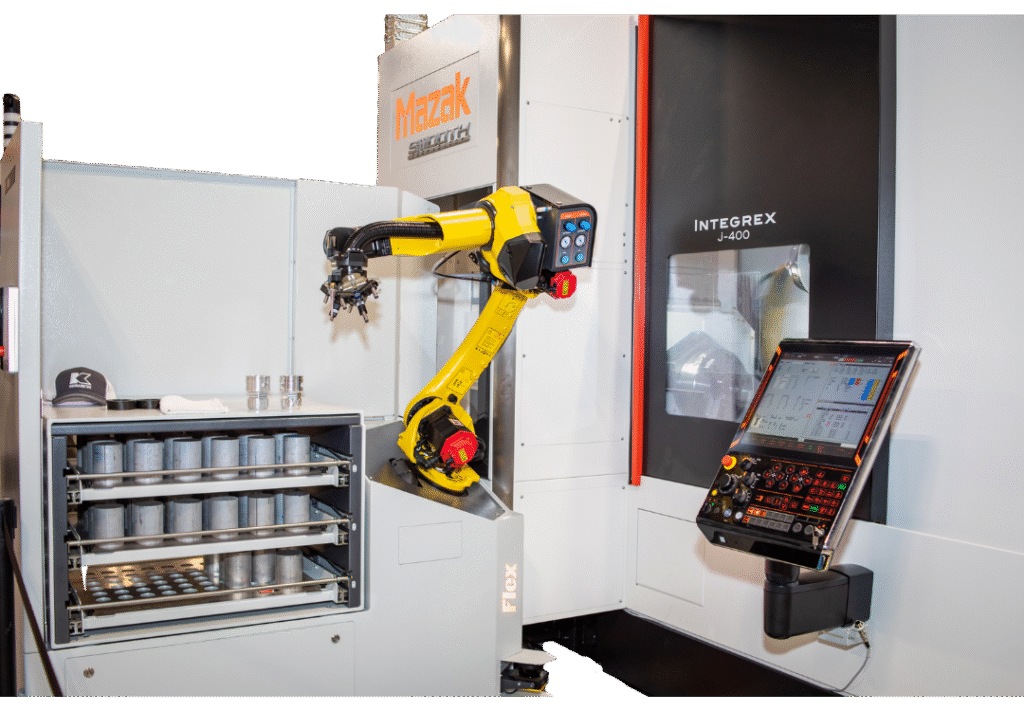

High-performance CNC machines and industrial machining automation work together to deliver the precision, repeatability, and throughput manufacturers require. AW Miller provides precision manufacturing equipment capable of handling complex geometries, demanding tolerances, and extended production cycles to maximize spindle uptime and reduce setups. In addition, when paired with automation, these systems eliminate bottlenecks, reduce manual intervention, and strengthen overall process control. As a result, engineers gain predictable cycle times, improved machine-to-machine communication, and more efficient resource utilization. This integrated approach streamlines machining workflows, enhances part flow, and enables manufacturers to scale production with consistent quality.

At AW Miller, we deliver machining solutions engineered for the complex demands of modern manufacturing. Our systems include 5-axis and multitasking machines for advanced part geometries, vertical and horizontal machining centers for high-accuracy production, and precision grinding systems for tight-tolerance finishing. We also support automation technologies that enhance throughput and stabilize workflow across the shop floor. Our goal is to provide equipment and support that strengthen process capability, maintain quality, and keep operations performing at their highest level.

AW Miller Sales Engineers deliver proven manufacturing technology solutions across New York, Pennsylvania, New Jersey, Maryland, and Quebec. With deep expertise in CNC equipment and automation, our team helps manufacturers identify the right machines to strengthen production processes. Our selection of industry-leading platforms ensures engineering and operations teams have access to the performance and capabilities needed to optimize throughput and maintain long-term productivity.

The Markforged FX10 brings flexibility and efficiency to the shop floor with the capability to print both composite and metal-ready components. Its advanced Onyx material, reinforced with continuous carbon fiber, delivers the strength and rigidity needed to replace machined aluminum parts. The FX10 also supports specialized materials, including food-safe and flame-retardant options, expanding its use across demanding industrial environments. By producing functional tooling, fixtures, and end-use parts in-house, manufacturers reduce lead times, cut costs, and keep production moving without interruption.

Composite and metal 3D printing systems unlock new opportunities on the shop floor by providing fast, cost-effective ways to produce functional parts, tooling, and fixtures. Composite platforms deliver lightweight, durable components that rival traditional metals, while metal 3D printing equipment enables complex geometries and high-performance applications that would be costly or time-consuming to machine. These capabilities allow manufacturers to bypass long lead times, eliminate the need for custom tooling, and respond quickly to design changes or production needs. When additive manufacturing is paired with CNC machining, printed near-net-shape parts can be finished with the precision and surface quality required for demanding applications. This combined approach reduces production costs, accelerates turnaround times, and gives manufacturers greater agility across modern shop-floor operations.

AW Miller is committed to supporting manufacturers with technology and expertise that strengthen every stage of production. From advanced CNC machining centers and automation systems to industrial 3D printing platforms and dedicated engineering support, we deliver solutions designed to improve workflow stability, reduce operational friction, and enhance overall productivity. Our focus is on enabling manufacturing engineers to solve challenges with confidence, maintain consistent quality, and adapt to the evolving demands of modern production. With proven equipment, responsive service, and a long-standing commitment to technical excellence, AW Miller is a partner dedicated to helping manufacturers achieve reliable, long-term success.