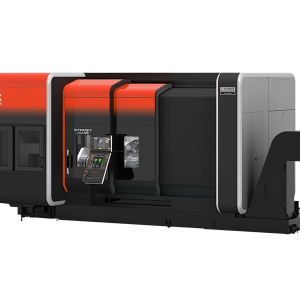

Variaxis j-500

<td>15432 lbs</t

r><t< yoastmark=””>d>2 ” to 22 “</t<><t< yoastmark=””>r></t<>

<td>18 lbs</tdtable>

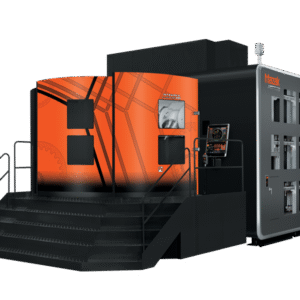

Variaxis j-500/5X

<t<;;;;;;;;; yoastmark=””>r></t<>

<th>Z-axis></th></th<th>X-axis<!–th>

1181 IPM |

| Y-axis> |

1181 IPM |

| Z-axis |

1181 IPM<!–td></th

<table>pan=”3″>TableTable sizeΦ19.69″ × 15.75″Max. workpiece sizeΦ19.69″ × 13.78″Max. load (evenly distributed)441 lbsSpindleTool shankCAT No.40Max. spindle speed&gt;12000 rpmMax. torque (40%ED)48 ft-lbsMax. torque (cont. rating)35 ft-lbsd>Spindle motor (40% ED)11 kW (15 HP)Spindle motor (cont. rating)7.5 kW (10 HP)Automatic tool changerTool storage capacity18Max. tool diameterΦ4 “Max. tool diameter (without adjacent tool)Φ5 “<!–tr>Max. tool length (from gauge line)12 "Max. tool weightTravelX-axis14 "Y-axis22 "20 ">A-axis-120° ~ +30°Distance from table top to spindle nose (table horizontal)owspan=”3″>Rapid traverse rateMachine size>Machine width × length (MAZATROL SmoothG)101 ” × 127 “Machine height112 “Machine weight<!–

>

| s=”yoast-text-mark”>an=”3″>Table |

Table size |

Φ19.69″ × 15.75″ |

| Max. workpiece size |

Φ19.69″ × 13.78″ |

| Max. load (evenly distributed) |

441 lbsd> |

| Spindle |

Tool shank |

CAT No.40 |

| Max. spindle speed</th> |

12000 rpm</td></td> |

| Max. torque (40% ED) |

48 ft-lbs |

| Max. torque (cont. rating) |

35 ft-lbsd> |

| Spindle motor (40% ED)<!–th> |

11 kW (15 HP)d> |

| Spindle motor (cont. rating) |

7.5 kW (10 HP)> |

| Automatic tool changer |

Tool storage capacity |

18 |

| Max. tool diameter |

Φ4 “ |

| Max. tool diameter (without adjacent tool) |

Φ5 “ |

| Max. tool length (from gauge line) |

12 “ |

| Max. tool weight |

18 lbs |

<tr>

Travel |

X-axis</th>

| 14 “ |

| Y-axis |

22 “ |

| Z-axis> |

20 “ |

| A-axis |

-120° ~ +30° |

| Distance from table top to spindle nose (table horizontal) |

2 ” to 22 “ |

| Rapid traverse rate |

X-axis |

1181 IPM |

| Y-axis |

1181 IPM |

| Z-axis |

1181 IPM |

| Machine size |

Machine width × length (MAZATROL SmoothX) |

101 ” × 127 “ |

| Machine height |

112 “ |

| Machine weight |

15432 lbs |

–>

|

</t