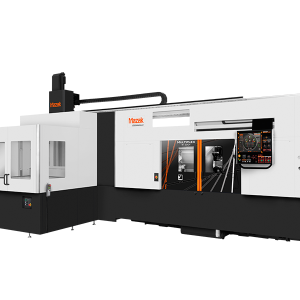

Enhanced Performance with Dual-Spindle CNC Automation

The Mazak Multiplex W-200 delivers a powerful combination of multitasking capabilities and high-throughput performance in a compact, intelligent design. With twin synchronized spindles, it effortlessly machines all part surfaces at once, allowing simultaneous processing of two components for both chucker and shaft applications. Each spindle offers identical power and precision, ensuring uniform performance regardless of the part configuration. Designed for maximum flexibility, the W-200 thrives in high-mix environments and supports advanced turning processes, making it a top choice for manufacturers focused on accuracy, speed, and CNC automation.

Compact and Intelligent Design for Lean Manufacturing

Built for demanding production environments, the Multiplex W-200 optimizes floor space while maintaining machining integrity. Its compact footprint supports automation processes with minimal setup. As a result, it reduces production lead time and operational overhead. Despite its size, it delivers consistent part performance on complex applications, meeting tight tolerances without compromising speed or quality. This machine supports manufacturers looking to streamline their workflows with modern multitasking solutions.

Competitive Manufacturing with Mazak Technology

The Mazak Multiplex turning center offers a complete multitasking solution that combines milling and turning in a single, continuous process. This integration speeds up production, improves part consistency, and boosts overall efficiency. Its precision and flexibility make it ideal for a wide range of machining tasks. With built-in CNC automation, it minimizes manual handling and reduces downtime, creating a smarter, more streamlined manufacturing environment.

Compare to other Mazak Multi-Tasking Machines for Sale