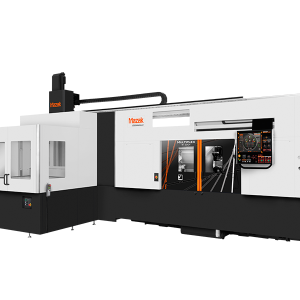

High-Precision Machining Capabilities for Complex Part Production

The Mazak Integrex i-450H AG delivers high-precision machining across a wide range of materials and geometries. It handles solid billets, castings, and highly contoured components with consistent accuracy. This advanced 5-axis platform is designed for medium to large parts that demand tight tolerances, and it supports accurate positioning and complex tool angles. As a result, manufacturers can machine all surfaces in a single setup. This makes the system well suited for high-mix, high-precision industries such as aerospace and energy.

Multi-Surface Machining and Advanced Gear Production

The i-450H AG excels at multi-surface machining. It includes Mazak’s SMOOTH Gear Cutting software suite with Gear Skiving, Gear Hobbing, and Gear Milling functions. These capabilities support high-accuracy production of internal and external spur, helical, and spline gears. Therefore, the machine is ideal for gear-intensive applications that require repeatable accuracy and uninterrupted workflow.

Optimized for Automated Machining Environments

The Integrex i-450H AG integrates easily with automated systems. It works well with robotic part loaders, pallet changers, and other automation platforms. Intelligent tool path control maintains accuracy across challenging part geometries. This automation-ready design reduces manual handling and shortens cycle times. It also increases spindle uptime, which supports higher productivity and operational efficiency.

A Scalable Solution for Precision Manufacturing

The i-450H AG offers a scalable platform for manufacturers focused on long-term performance. It also operates effectively as a standalone machine or within a fully integrated smart manufacturing cell. In addition, its advanced software, flexible tooling support, and automation compatibility align with modern machining best practices. With these strengths, the Integrex i-450H AG provides the precision, consistency, and workflow efficiency needed for next-level production.

Compare to other Mazak Multi-Tasking machines for sale