class=”yoast-text-mark”>lass=”yoast-text-mark”>lass=”yoast-text-mark”>lass=”yoast-text-mark”>lass=”yoast-text-mark”>lass=”[–thread-content-max-width:32rem] @[34rem]:[–thread-content-max-width:40rem] @[64rem]:[–thread-content-max-width:48rem] mx-auto flex max-w-(–thread-content-max-width) flex-1 text-base gap-4 md:gap-5 lg:gap-6 group/turn-messages focus-visible:outline-hidden” tabindex=”-1″>

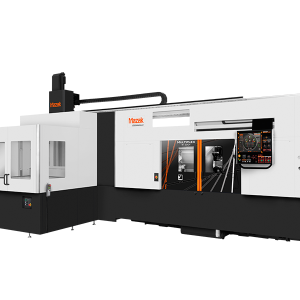

- 5-Axis Machining Capability – Enables complete part processing in a single setup for greater precision and efficiency.

- High-Torque Milling Spindle (12,000 rpm) – Delivers powerful cutting for large and complex components.

- Dual Turning Spindles – Facilitates full part transfer and multi-surface machining.

- Extended Y-Axis Travel – Enhances flexibility for handling deep and contoured parts.

- MAZATROL SmoothAi CNC Control – Provides AI-driven programming, digital twin simulation, and real-time diagnostics.

- Automation-Ready Architecture – Seamlessly supports gantry loaders, robotic systems, and bar feeders.