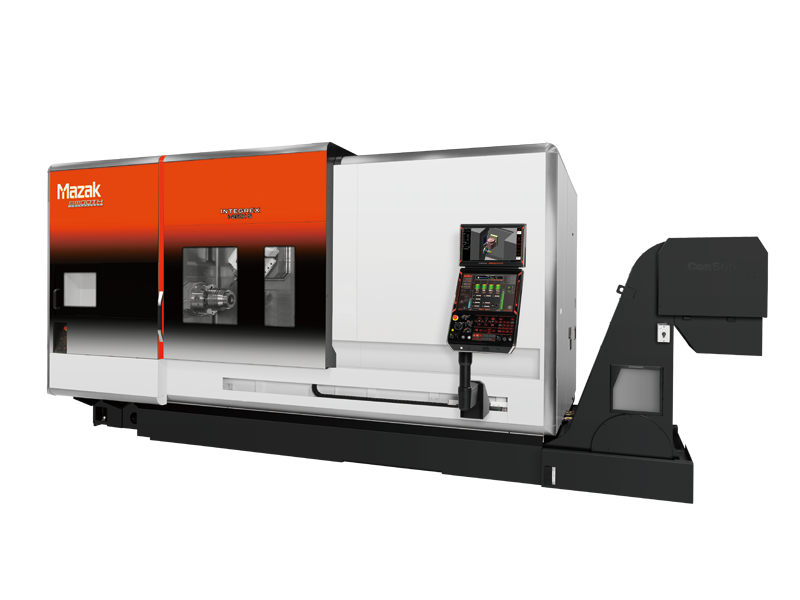

Integrex i-350H CNC Tooling Solutions Optimized for Heavy-Duty Precision

The Mazak Integrex i-350H delivers high-performance machining for large, complex parts with speed and precision. Featuring full 5-axis capability, an expanded work envelope, and high-speed spindles, it enables complete part processing in a single setup. As one of Mazak’s most advanced high-speed machining solutions, it integrates turning, milling, and drilling into a compact platform designed for modern production demands. Additionally, the i-350H supports a wide range of CNC tooling solutions, making it an ideal choice for precision-focused manufacturers seeking efficiency, flexibility, and reliability in a single machine.

Efficient Setup for Demanding Manufacturing Applications

Engineers and machinists benefit from the 12,000 rpm compact milling spindle and robust main and second spindles. These high-performance components enable the i-350H to handle demanding geometries with efficiency. In addition, these high-speed machining solution are designed for quicker cycle times and reduced tool wear. It also includes extended Y-axis travel and a larger bore to increase versatility for large-diameter workpieces. It integrates seamlessly into automated environments, fitting well in shops that rely on industrial machining applications across varied sectors like aerospace, automotive, and medical. The Mazatrol SmoothAi CNC control system boosts programming efficiency with AI support, real-time simulation, and digital twin integration. This allows shops to minimize setup errors, enhance repeatability, and increase uptime. Moreover, thermal control systems preserve dimensional integrity over long shifts.

Flexible Integration, Scalable Results

For manufacturers seeking adaptable systems, the Integrex i-350H CNC tooling solutions enable fast changeovers and support a wide range of tool libraries. Its seamless compatibility with robotic automation, gantry systems, and bar feeders allows shops to scale operations without reconfiguring existing layouts. This level of flexibility is especially valuable in hybrid and high-mix environments, where rapid adjustments to part variety are key. In addition, advanced tool management and digital integration help reduce setup time while maintaining consistent productivity. As production needs evolve, the i-350H provides the responsiveness and efficiency modern manufacturers require.