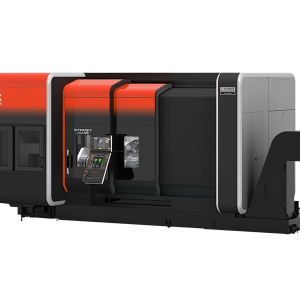

The Mazak Integrex i-250H is a compact, high-performance multi-tasking machine that combines turning, milling, and Y-axis capabilities in one setup. Ideal for job shops and production floors, it integrates seamlessly with Vertical CNC Systems and features Advanced Tool Changers for fast, efficient operation. Designed for engineers and machinists who need speed, precision, and flexibility.

Integrex i-250H Features:

- Mazatrol SmoothAi CNC Control: Offers intelligent programming, AI-driven diagnostics, real-time monitoring, and digital twin technology.

- Flat-Front Construction: Enhances operator access and simplifies integration with automation systems.

- Compact Footprint: Designed to maximize floor space while maintaining high-performance machining.

- Automation-Ready: Supports robotic part loading and lights-out manufacturing strategies.

- Tight Tolerance Capabilities: Ideal for high-precision industries like aerospace, medical, and complex general machining.