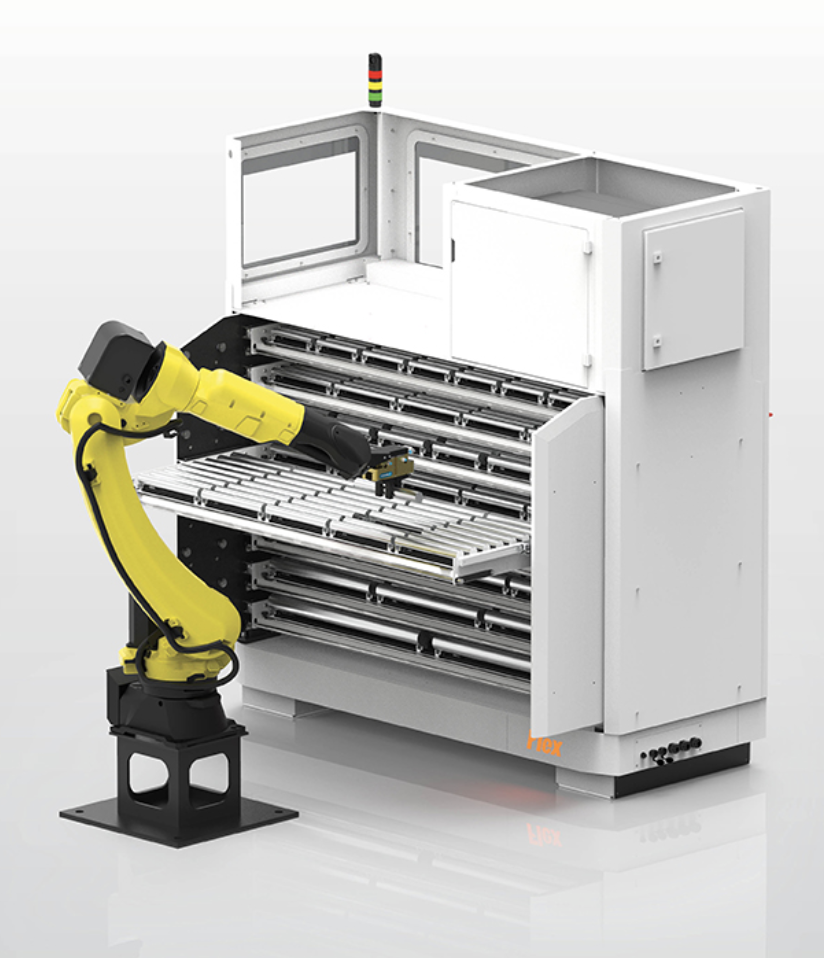

Engineered for MEGA Capacity CNC Loading

The Agile Flex MEGA S is an engineered MEGA-capacity CNC loader, purpose-built to precisely handle large, heavy parts. For example, each drawer supports up to 400 kg (≈ 880 lbs), providing structural strength for demanding machining operations. In addition, its multi-drawer configuration is expandable for up to 8 drawers for extended, unattended production of high-volume or heavy-part applications. It also features a modular design, adaptable to various part geometries and production requirements so that engineers can configure the system to meet specific CNC demands and optimize throughput with maximum reliability.

Optimized Heavy-Part CNC Automation Workflow

As part of a comprehensive heavy-part CNC automation solution, the Agile Flex MEGA S integrates smoothly with existing machine tools. For example, it supports shafts and components up to 63” in length and handles varied diameters and geometries via configurable nests. In addition, the system’s advanced drawer mechanism and robust robotic interface ensure precise part loading and unloading, which minimizes machine downtime and manual intervention. As a result, operators gain improved spindle utilization, reduced labor costs, and enhanced consistency across production runs.

Versatile Load Robotic System for Smart Production

This load robotic system is designed for scalability, seamless integration, and efficient operation. The Agile Flex MEGA S incorporates the intuitive Agile Go! controller, enabling quick setup and operation without specialized robot programming expertise. Engineered to handle a wide range of heavy parts and payloads, it supports continuous, lights-out production with exceptional reliability. Purpose-built for advanced manufacturing environments, the MEGA S integrates effortlessly into Industry 4.0 ecosystems and future-ready automation strategies.