Machining solutions in the automotive industry deliver advantages in speed, precision, and repeatability—essential attributes for the high-volume, tight-tolerance production demands. As vehicles become more advanced, the need for precise and consistent manufacturing keeps growing. Modern CNC technology supports this demand through advanced digital automation, reducing the risks of human error and process variability. Today’s CNC systems enable efficient, high-volume production of identical components from a single programmed specification. Maintaining tight consistency is essential in automotive manufacturing, where minor deviations in a single engine component can cause performance issues or system failure. Since A.W. Miller has decades of experience, our team is prepared to help manufacturers meet these high standards. Each of our engineers is equipped to align CNC technologies, materials, and machine configurations with the precise requirements of each application. Contact us to learn more!

CNC machines are widely used in producing automotive components such as:

Automotive machining processes benefit from CNC technology because it integrates with CAD programming for standardization and customization—making it ideal for low- to high-volume manufacturing.

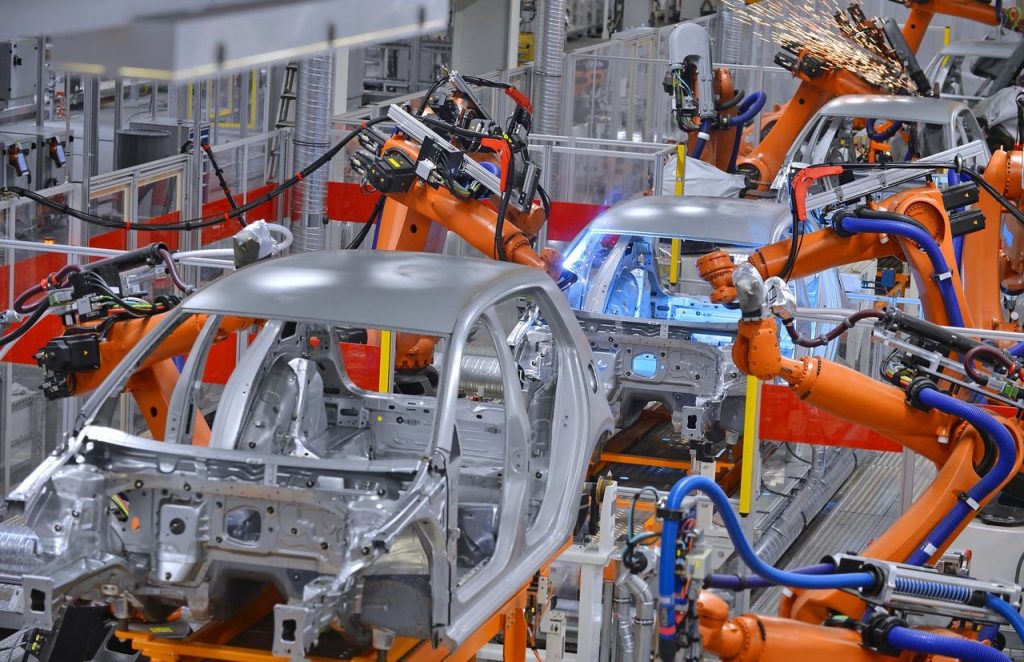

The introduction of 5-axis CNC machining has revolutionized production within the automotive sector. This technology simplifies the manufacturing of intricate geometries by reducing the need for multiple setups and improving dimensional accuracy. In addition, 5- axis CNC machining solutions provide is significant due to faster cycle times and superior component precision, critical in all automotive applications.

5-axis CNC machining has redefined automotive manufacturing solutions by enabling faster, more accurate production of complex parts. It eliminates multiple setups, reduces manual handling, and boosts precision—key for engine components, drivetrain parts, and structural assemblies. While the initial cost is higher, the gains in cycle time reduction and part consistency deliver long-term value for high-demand operations.

Mazak offers advanced 5-axis CNC systems built to meet the speed and precision demands of modern automotive production. With flexible configurations and automation-ready platforms, Mazak machines handle materials like stainless steel and cast iron with ease. From suspension brackets to off-road components, these systems help manufacturers cut cycle times, maintain tight tolerances, and increase throughput—all essential in large-scale automotive machining.

Routine maintenance and long-term mechanical reliability are critical concerns in the automotive sector, particularly regarding engine systems and startup mechanisms. Over time, components in these systems are damaged, leading to diminished performance and increased risk of failure. The advancement of automotive machining, particularly through CNC manufacturing, is now mitigating these issues with greater precision and operational efficiency.

In particular, advanced CNC machining supports the fabrication of complex automotive components that exceed the durability and tolerance levels achievable with conventional methods. Furthermore, quick mass production and precise programming capabilities offer significant benefits in cost control and manufacturing reliability. Consequently, in high-volume automotive applications, consistency and precision remain critical performance factors.

Recent developments in artificial intelligence (AI) are further enhancing the capabilities of CNC machinery. AI-driven systems are optimizing key aspects of automotive machining, including:

These advancements are improving output quality and workflow efficiency across the automotive manufacturing sector. AI-powered CNC machines are now capable of automatically adapting machining parameters to ensure optimal results, even during complex production runs.

Current industry trends indicate a strong approach toward deeper AI and CAD software integration. Future systems are expected to:

Generative design will play a critical role in advancing automotive applications, allowing manufacturers to create lighter, stronger, and more efficient parts that improve vehicle performance while reducing material waste.

AI-assisted CNC machining is proving instrumental in the development of self-driving vehicles, which demand higher precision in electrical and mechanical components than conventional cars. As digital systems in autonomous vehicles continue to advance, the demand for consistent, micron-level tolerances in sensor housings, control units, and other components increases.

Automotive machining technologies are being leveraged to produce these high-precision parts at scale. Additionally, AI integration allows machines to adjust in real time, ensuring each part meets the stringent standards required for autonomous operation.

AW Miller is proud to offer a team of Mazak certified applications engineers that will assist you with service requests in a timely manner to decrease down time. We will also help you to avoid service requests with routine maintenance tips. Please click here for more information.

If your team needs assistance with learning how to use the CNC machinery and technology, Mazak offers a variety of training classes. These will ensure your automotive manufacturing teams are up-to-date on how to use and maintain the machines effectively. Please contact us to learn more about these training classes.

The automotive industry involves the production of highly customized vehicles, with each model requiring unique parts, fixtures, and finishes. This complexity also brings challenges, including strict launch schedules, budget constraints, and regulatory standards. Engineers must consistently develop vehicles that improve fuel efficiency, performance, safety, and aesthetics. As innovation advances, 3D automotive applications are becoming essential in both prototyping and end-use manufacturing. Incorporating 3D printed car parts enhances customization, improves material performance, and accelerates production timelines—supporting a broad range of automotive applications. These technologies offer structural integrity and high-quality surface finishes, helping manufacturers meet design and functional goals efficiently. Contract 3D printing services allow manufacturers to prototype parts using industrial systems before full-scale production. This minimizes risk, ensures part performance, and supports faster decision-making.

Originally centered on rapid prototyping, 3D printing in the automotive industry has expanded to include digital inventory, legacy part replacement, and custom tooling. On-demand production helps reduce warehousing costs, accelerate delivery times, and support sustainability by minimizing material waste and lowering carbon emissions. Markforged’s industrial-grade 3D printing solutions are well-suited for producing high-strength components such as brackets, mounts, fixtures, and high-temperature jigs. Automotive teams also use Markforged systems to reproduce discontinued parts for legacy vehicles, blending modern engineering with classic design requirements. This approach enables cost-effective restoration and customization while maintaining structural performance and reliability.