Aerospace Manufacturing Standards

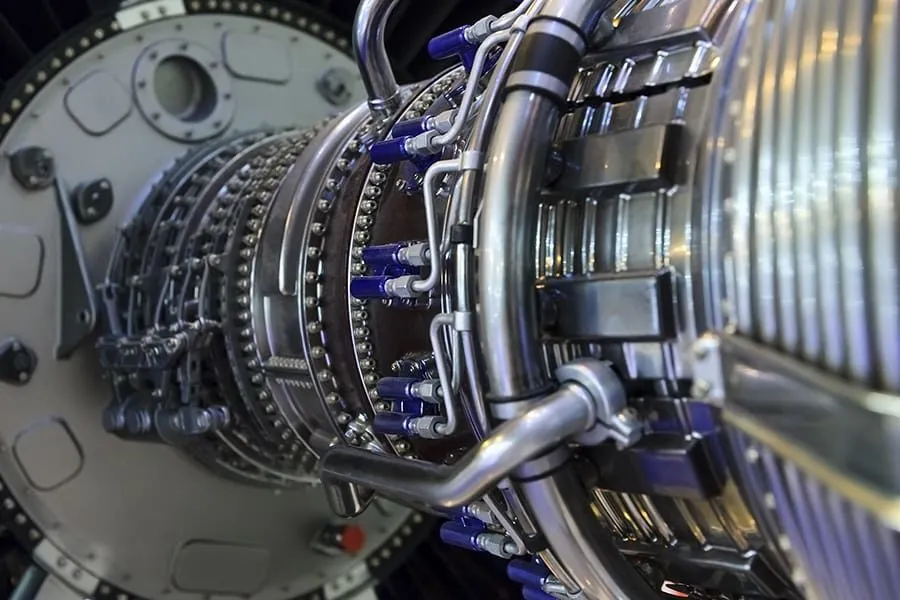

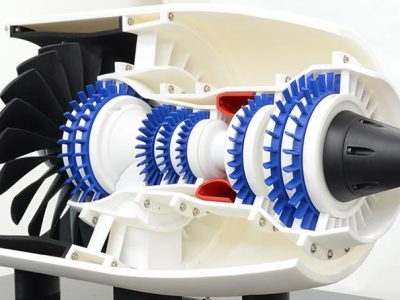

The aerospace manufacturing industry demands a higher level of precision and accuracy to ensure safety, durability, and performance of the aircraft. Each component, from bushings to structural assemblies, must meet tight tolerances and adhere to strict quality benchmarks. The industry revolves around producing millions of parts for aircraft and spacecraft, with consistency and accuracy at the core of every process. In this environment, high-performance materials are the standard. For example, titanium, superalloys, stainless steel, and aluminum must all be machined efficiently to retain structural integrity. Every detail matters in the aerospace cnc machining industry where precision directly impacts performance, safety, and regulatory compliance.