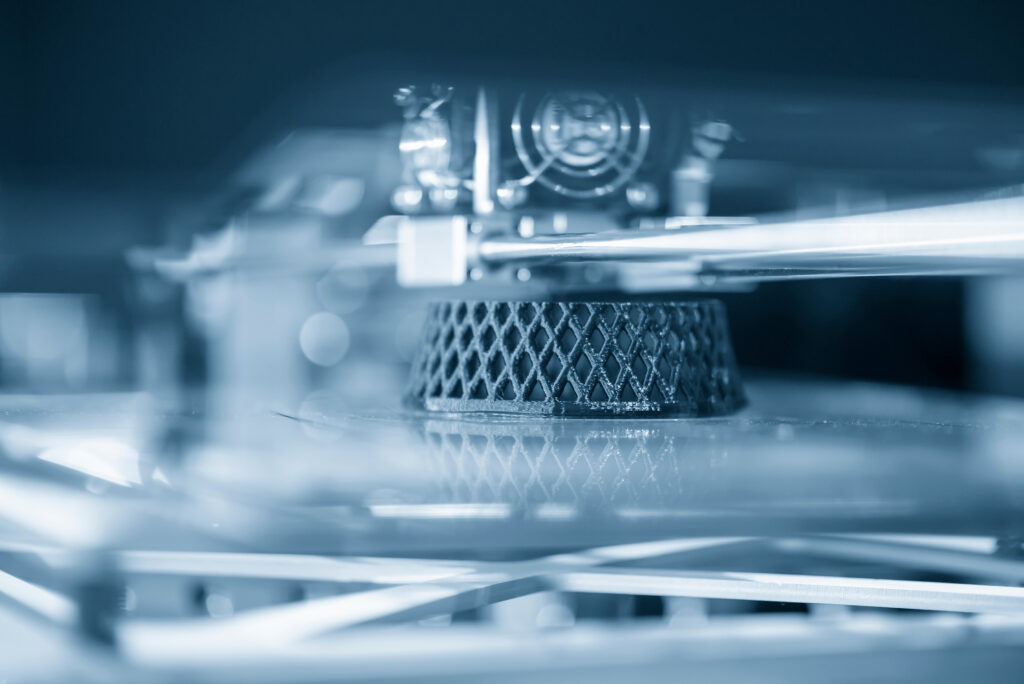

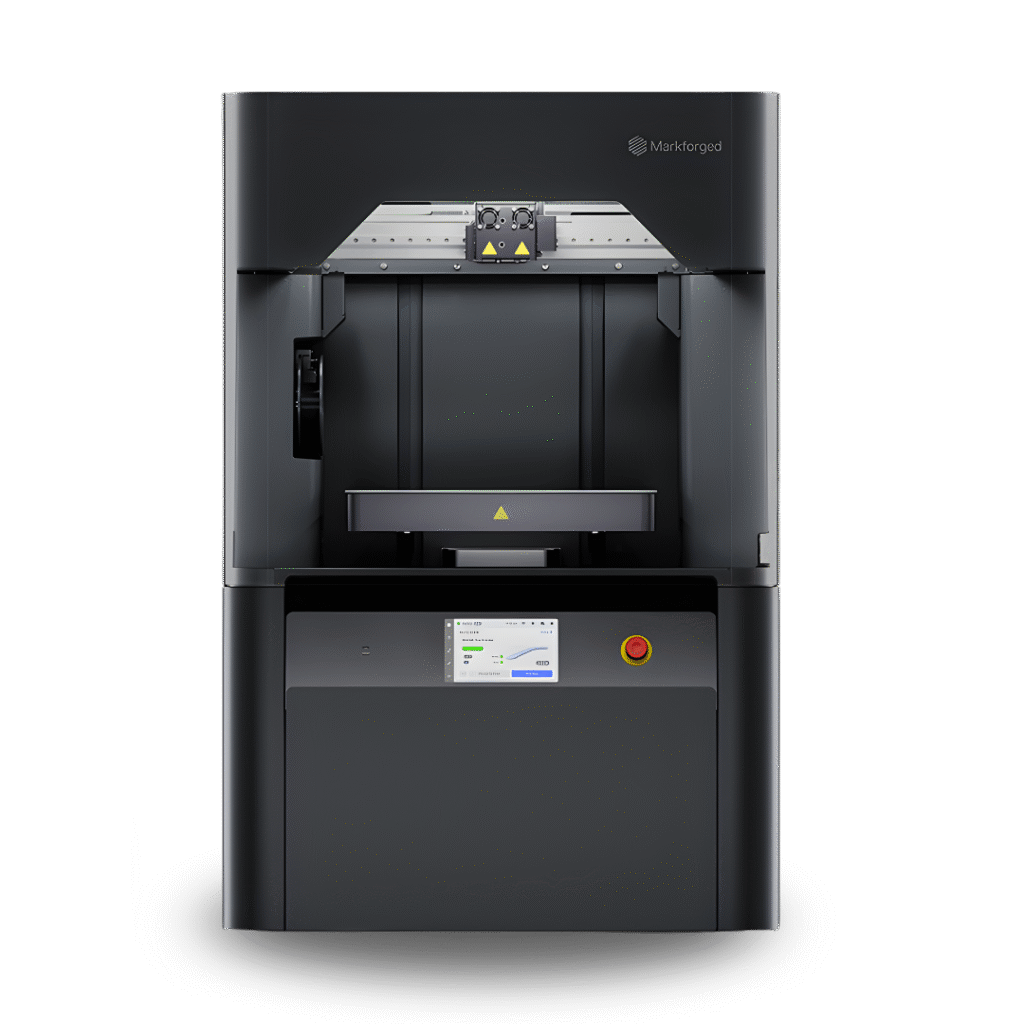

AW Miller delivers industrial 3D printer installation services with a focus on system reliability, process stability, and long-term performance. Each 3D machine installation is executed by experienced engineers who understand the operational requirements of modern machine shops, manufacturing facilities, and R&D environments implementing additive manufacturing workflows.

From initial site planning through post-installation validation, all installation and training activities are handled directly by AW Miller. This includes logistics coordination, equipment placement, system setup, and operator onboarding to ensure production readiness from day one while minimizing disruption to existing operations.

Prior to delivery, a structured site assessment is conducted to support proper 3D printer installation and long-term serviceability. This evaluation ensures facility readiness and alignment with system requirements, including:

This proactive planning phase reduces installation delays and supports a smooth transition from delivery to operation.

Once your equipment is onsite, our certified engineers manage the machine installation process, including:

Our team ensures your machine is fully operational and ready for production before we leave your facility.

The time required for installation depends on the number of units, machine type (composite, metal, or polymer), and any auxiliary equipment such as wash stations or sintering furnaces. We work with your schedule to minimize downtime and ensure a fast, efficient launch.

Upon purchase, AW Miller provides an estimated timeline and coordinates delivery, setup, and training to keep your project moving.

AW Miller provides expert 3D machine installation and support to help you get up and running quickly. Before delivery, our team assesses your facility layout, power needs, material handling areas, and maintenance access to ensure a smooth setup process.

Once installed, we offer ongoing industrial 3D printing support, including:

Our additive manufacturing support services are built to grow with your operation—whether you’re starting with one printer or managing multiple systems.

We offer hands-on 3D printer training tailored to your team’s experience level. Training includes:

These additive manufacturing training programs help your team master the technology quickly and confidently.