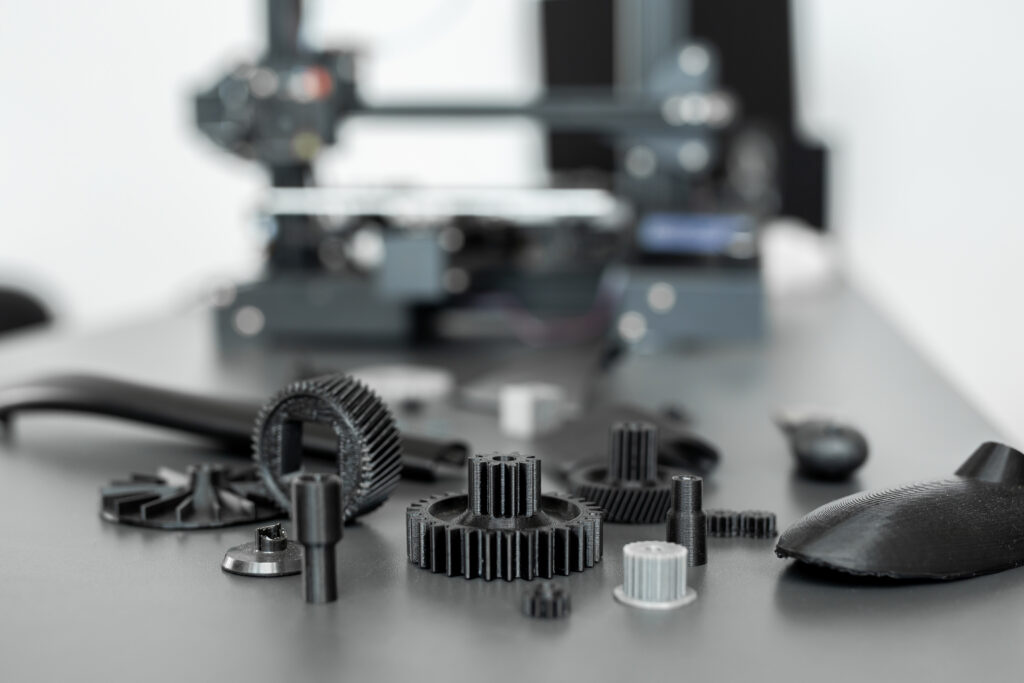

Our 3D applications engineering services also support manufacturers in the effective adoption and optimization of their 3D printing technologies. For example, engagements are focused on evaluating production requirements, identifying process constraints, and implementing application-specific solutions that improve part quality, reduce lead times, and increase overall workflow efficiency.

Our additive manufacturing engineers bring hands-on experience with industrial 3D printing systems, digital manufacturing software, and advanced materials. Whether supporting initial system implementation or scaling an established additive operation, technical guidance is provided across the product lifecycle from early concept validation through production-ready deployment.

Our engineers will begin with a detailed assessment of existing manufacturing processes, application requirements, and long-term production objectives. Based on this analysis, we can provide informed recommendations for additive technologies, materials, software platforms, and automation strategies aligned with operational goals.

Applications engineering support includes:

This collaborative process ensures additive manufacturing solutions meet defined performance benchmarks for prototyping, low-volume production, and functional end-use components.

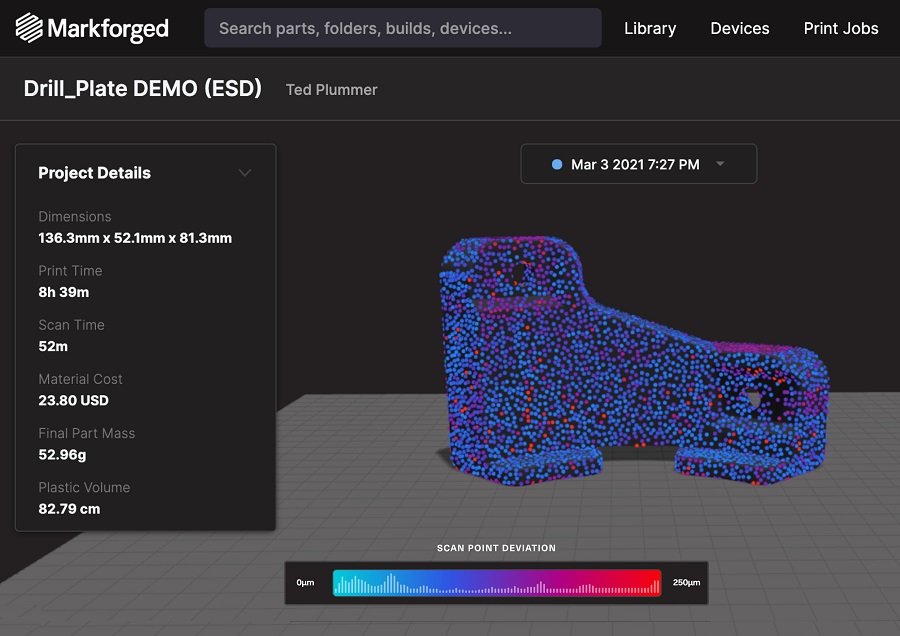

To support closed-loop digital manufacturing workflows, AW Miller provides access to advanced software platforms including Geomagic Design X, Geomagic Control X, and Markforged Blacksmith.

These tools integrate directly with additive manufacturing systems, providing engineers with greater visibility, control, and repeatability across the production process.

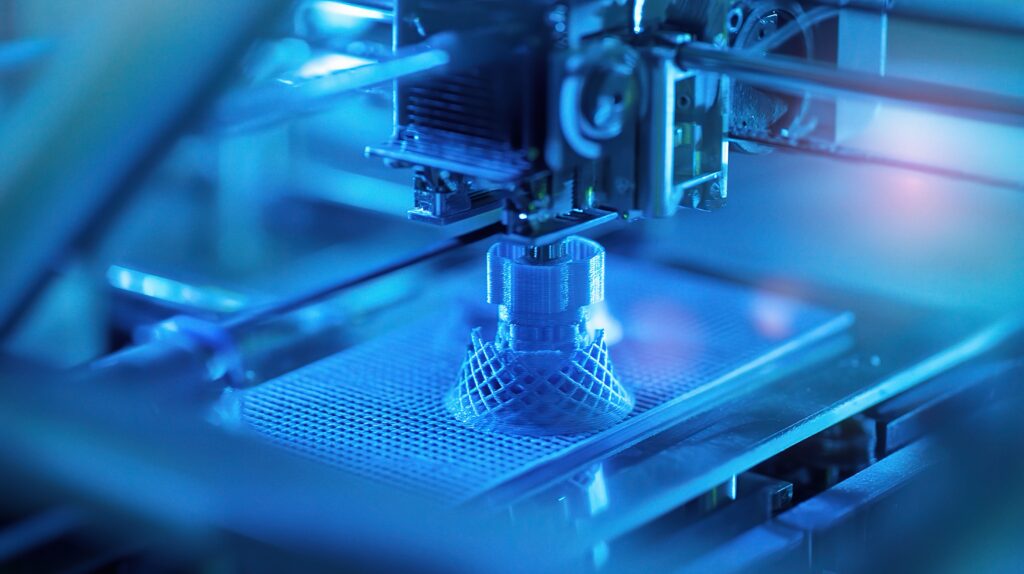

Through application tuning and validation, additive systems are configured to align with specific part requirements and production objectives. This ensures consistent and predictable performance across both prototype and production use cases.

Application tuning workflows include:

By aligning digital process parameters with physical part performance, AW Miller also supports reliable implementation of industrial 3D printing technologies.

Our 3D applications engineering services benefit manufacturers across a range of industries: