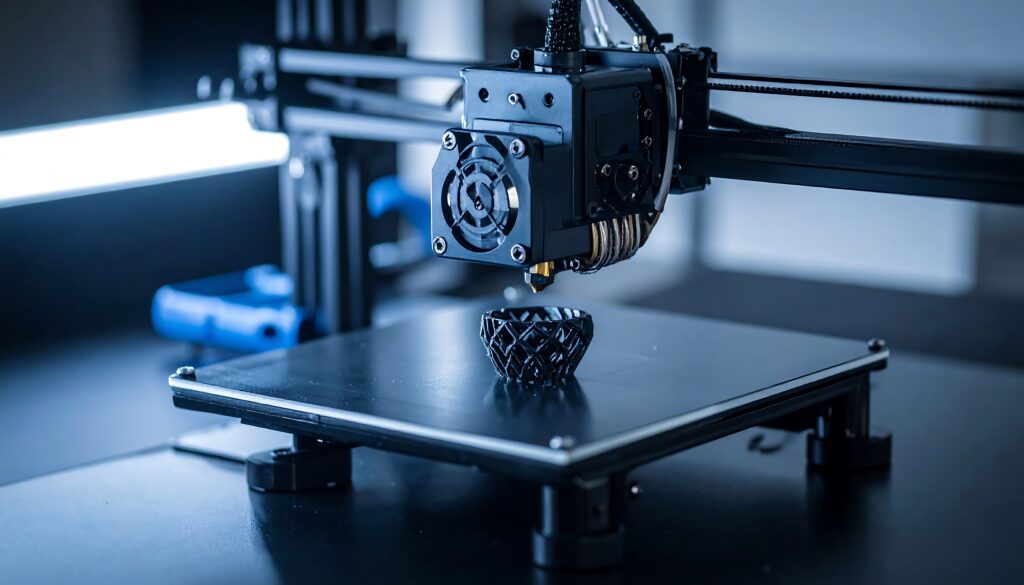

AW Miller’s 3D printer training programs and additive manufacturing courses are designed to build technical proficiency and expand in-house capabilities across a range of experience levels. These programs provide structured, hands-on instruction aligned with current industrial 3D printing practices and real-world manufacturing requirements.

As additive manufacturing continues to influence product development, supply chain strategies, and production workflows, technical competency has become increasingly critical. AW Miller’s training offerings support both individuals and teams in the effective adoption and application of 3D printing technologies, covering foundational operation, material selection, process optimization, and advanced design and production methodologies.

AW Miller’s training programs offer flexible and comprehensive content suited for various experience levels:

Length of time to complete: 1/2 Day

Cost: $200 per person

Length of time to complete: 1 Day

Cost: $400 per person

Length of time to complete: 1 Day

Length of time to complete: 1/2 Day

AW Miller’s 3D printing training programs are developed with a strong emphasis on industry relevance and applied learning. Instruction is structured to reflect real-world manufacturing environments and current additive manufacturing practices, ensuring technical concepts translate directly to production use cases.

Key program attributes include:

Collectively, these programs prepare participants to contribute effectively to additive manufacturing initiatives and support career development in additive production, design, and engineering disciplines.

3D printing education provides participants with a comprehensive understanding of both the theoretical principles and practical application of additive manufacturing technologies. Through structured coursework, professionals develop the technical skills required to effectively implement and support additive manufacturing within engineering and production environments.

Key learning outcomes include:

As additive manufacturing continues to transition from prototyping to production-focused workflows, formal training has become an increasingly important component for organizations seeking to remain competitive.